Planning and implementing electrical installations yourself, ...but how?

- HANDYMAN Marius

- Dec 1, 2024

- 33 min read

Hey, are you about to plan an electrical installation for your apartment or house? Or maybe you've already received a quote and are wondering if it could be done more cheaply? Then you've come to the right place, because you can actually do it cheaper if you do it yourself! In the following, I would like to provide you with useful tips and the knowledge you need to confidently plan and implement your electrical installation.

What needs to be considered for a DIY electrical installation?

A DIY electrical installation has many advantages. Firstly, you can save money by avoiding expensive installation costs. Secondly, you have full control over the equipment in your apartment or house, so you can design your electrical installation entirely according to your wishes. You can also put your craftsmanship to the test and expand your skills. By planning and implementing your electrical installation independently, you will also learn a lot about how circuits, cable connections and electrical engineering work. Flexibility is also a great advantage - you can make changes to your electrical installation at any time without having to ask anyone for permission or help. However, you should bear in mind that an electrical installation always involves a certain degree of danger and it is important to observe the necessary safety measures. However, if you comply with these, you can look back on your DIY project with joy and pride.

It is important to note that work on electrical systems is reserved exclusively for trained specialists, which certainly makes sense. The following tips are therefore not to be understood as instructions and everyone should be aware of the legal and safety-related risks. It is important to plan and implement an electrical installation professionally, as electricity is a very dangerous element. Faulty installations can not only lead to personal injury, but can also cause considerable damage to property. A professionally executed electrical installation ensures a high level of safety and a reliable power supply in your living space.

But what is actually required to stay within the legal framework? From a legal point of view, you actually need a master electrician to approve your system, but they don't necessarily have to have built the system themselves. Presumably everyone can imagine that with today's labor costs, even specialist companies use untrained personnel to carry out work such as slitting, laying cables, filling and other preparatory work. So why shouldn't you simply carry out this work yourself? There really is no obvious reason not to, as long as you comply with all regulations and have the necessary skills.

However, the 5 safety rules for working with electricity should always be observed, which is why I would like to put them right at the beginning of this article!

So how should I proceed?

First of all, think about what work you are comfortable with and what you would like to do yourself. Many people decide on four clearly defined work steps for this question, which should not be missing from any electrical installation and are usually the most expensive:

1. Making the cable slots

2. Drilling the required sockets (sockets, switches, junction boxes)

3. Laying the required power cables

4. Plastering the box inserts and filling the cable slots

These four work steps are probably the most expensive in an electrical installation and at the same time the easiest. I deliberately say “the easiest” and not “the quickest”, as these steps cause the most working hours due to their scope. Conversely, this also means that you have the greatest savings potential here. However, there is of course still enough work left for the electrical contractor, as there are also steps in your new electrical installation that are best carried out by a professional:

5. Install sockets and light switches

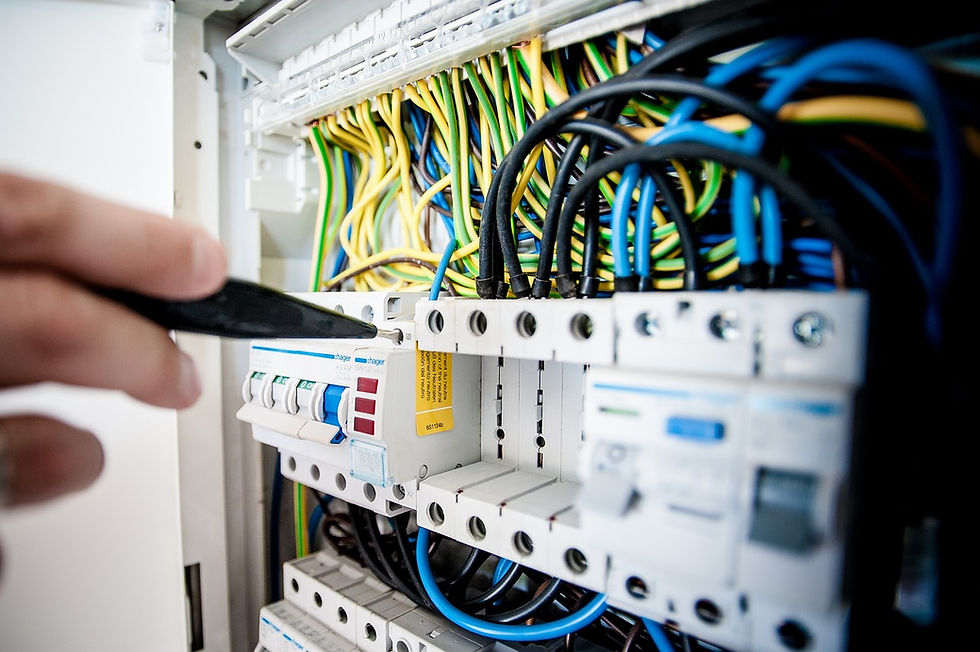

6. Install and connect the electrical sub-distribution board

7. Measuring and checking the new electrical installation including protective devices

Even if these steps should be carried out by the specialist company, I will go into them in more detail later to at least show you what the specialist company actually does.

Once you have defined which work you would like to do yourself, you need to look for a suitable specialist company and discuss your plans with them. It must be said that times have clearly changed here and many companies are quite open to such suggestions, as the preparatory work is not exactly popular and the beautiful final assembly remains in their hands. This is particularly important as the specialist company has to accept the system at the end and take responsibility for it. For many companies, it is a must that you plan the preliminary work together with them, that they come and take a look in between and that the sub-distribution and the final measurement remain in their hands.

What tools and materials are required to carry out an electrical installation yourself?

If you want to carry out an electrical installation for your apartment or house yourself, there are a few tools and materials that you will need. These include a voltage tester, needle-nose pliers, telephone pliers, side cutters, electrician's screwdriver (or directly an electrician's set), slot cutter, wire stripper, wire stripper, drill, cable ducts and cable ties, various cables (wires), fixing clips and nail clips, flush-mounted device box and flush-mounted device box with terminal compartment, plaster, plaster cup, putty set, putty (filler).

Depending on the type of electrical installation you want to carry out, additional tools and materials may also be required. To ensure that you have all the necessary items, you should consider the precise and prior planning of your electrical installation. It is important to use only high-quality and reliable materials to minimize safety risks and avoid problems later on. If you are unsure about which tools and materials you need, you should seek professional help or inform yourself in detail.

Start planning!

The basic planning

If you want to start planning, there are a few important things you need to bear in mind. An electrical installation includes the sub-distribution board, all the electrical cables, switches and sockets that are installed in a building and provide power and light. A correctly planned and installed electrical installation is crucial for the safety and comfort of your home. There is nothing worse than having a fuse blow as soon as you switch on a hairdryer or vacuum cleaner. You will also be very annoyed if you constantly have to search for a nearby socket for your vacuum cleaner, or if the right light switch is never where you need it. But since you have decided to do the planning yourself, you naturally have full control over the number and location of your sockets and light switches, which means that you can implement exactly the things that are important to you. You can also acquire a lot of knowledge about electrical engineering, which will definitely benefit you in the future.

First of all, you should get an overview of which rooms need to be supplied with electricity and how many sockets and switches you need. You shouldn't worry about the wiring later on, as it's all about offering you the greatest possible convenience in the future. Ideally, you should now create a floor plan of your four walls in which you define the positions and number of your sockets, light switches and any special kitchen appliances. Please also take into account the future position of furniture such as wardrobes, sofas, TVs, fitted kitchens, etc., as we want to avoid your sockets being covered by a closet, for example.

When it comes to the light switches, you should ensure that they are perfectly positioned for later operation; the height does not play a role here for the time being, as we will discuss the standard dimensions in electrical engineering later. When planning, however, you should already know that the number of light switches for a single lighting circuit is basically open at the top, so you could, for example, switch the bedroom lighting on and off from the entrance and also from both sides of the bed. Or you could also switch the hallway lighting from two, three or four different places. When positioning your switches, also think about what type of switches you want to use, as you can use single rocker switches or series switches with a double rocker. The advantage of series switches is that you only need a single flush-mounted box and your subsequent switch combination (number of frames) can be significantly reduced as a result. For example, if you have an eat-in kitchen with two lamp outlets in the living room and two in the kitchen, which should all be separately switchable, you can limit it to two switch boxes with two series switches, whereas with simple switches you would have to install four switch boxes:

Two series switches

Four simple switches

Which cables do I need and how are they laid?

Now you should determine the position of the cables and the type of cabling. It is very important to carry out detailed pre-planning to avoid mistakes and problems later on. Once the cables have been laid and the slots closed, it can be very annoying if you have forgotten a cable. To avoid mishaps, you should also draw the planned cable routing and the type of cables in your floor plan.

To do this, it is important to know the requirements and regulations for selecting cables and safety devices for your future sub-distribution board.

Structure of the sub-distribution board

There are, of course, regulations for the correct structure of a sub-distribution board, but there is still a lot of freedom and the possibility of individual, needs-oriented configuration. This is why sub-distribution boards from different electricians never look 100% identical, even if they all have to comply with the applicable regulations.

To meet today's standards, you should always plan your sub-distribution board with a little reserve. So if you can get exactly what you need with a 3-row sub-distribution board, use a sub-distribution board with 4 rows and so on. As you can now buy sub-distribution boards already equipped and the price is in the same range as a self-equipped sub-distribution board, I would generally advise you to do so. You will find countless offers for this and can also click on the image to go directly to the article.

Depending on your individual wishes and circumstances, it may also be necessary to replace individual components. It may play a role here whether you have an instantaneous water heater and/or an electric oven, for example. You may also decide to separate the light and socket circuits or to provide an individual circuit breaker (automatic circuit breaker) for each room, via which the light and sockets run together. All variants have their advantages and disadvantages, which is why the final decision can only be yours. However, I would recommend that you provide one fuse per room, as this will reduce the number of circuit breakers required and you will only need one supply line per room.

Otherwise, the basic structure and the equipment used is always the same, regardless of whether the cables are fed into the sub-distribution board from below or above. In this article, I am assuming that the supply line already exists and that your planned installation starts from the supply line (apartment or house feed).

Common supply cables for residential sub-distribution boards (TN-S system) with normal cable lengths and back-up fuses up to approx. 50A are, for example, NYM-J 5x10mm².

For apartment distribution boards with 63A back-up fuses (e.g. SLS switches), longer cable runs and electrical water heating, NYM-J 5x16mm2 is usually used. Please always bear in mind that your individual circumstances may well deviate from the standard and this must be checked on site. If you have installed a TN-C system, you will find a supply cable with only 4 cores and a missing neutral conductor (blue). However, this is not a problem for your subsequent installation because you will split the so-called PEN (green/yellow) into neutral and PE in your new sub-distribution board.

4 Adrig: L1 = brown / L2 = black / L3 = gray / PEN = green-yellow

5 Adrig: L1 = brown / L2 = black / L3 = gray / N = blau / PE = green-yellow

We can therefore see that the supply cable is the starting point of your new installation. It is fed directly into the overvoltage protection device (red component) of the sub-distribution board (L1, L2, L3) and from there into the terminal blocks. The neutral conductor and PE are fed directly into the terminal blocks. If it is a 5-core TN-S system and you have opted for a fully equipped sub-distribution board, the feed side of the UV would now be fully connected. However, if you have a 4-wire TN-C system, you must now split your PEN into PE and N. To do this, connect your PEN to the PE terminal block as normal and then connect a jumper from there to the N terminal block, splitting the PEN and allowing it to take over the PE and N functions.

Selecting the right cables

Various factors play a role in the selection of the correct cables: the fuse protection (circuit breaker), the cable length and the consumers to be supplied. In the electrical installation of living spaces relevant to us (surface-mounted and flush-mounted), NYM damp-proof cables are generally used, which differ only in the number of cores and the cable cross-section.

For normal residential circuits, use 16A circuit breakers and at best 2.5mm² NYM cables. If the circuits are purely lighting circuits, 1.5mm² NYM cables and 10A miniature circuit breakers can be used. With 16A protection, it is generally possible to use 1.5mm² NYM cables for all circuits, although it is now standard practice to use 2.5mm² NYM cables for mixed circuits (light and sockets) and for socket-only circuits, although there is no obligation to do so. For normal circuits (light and sockets), the following cable types are normally used:

As you can clearly see in the following pictures, these two power cables look completely identical at first glance and only differ in the cross-section of the individual cores. However, a direct comparison quickly reveals that the 2.5mm² cores are significantly thicker. You also notice the difference very quickly during installation, as the 2.5mm² NYM cables are much more difficult to lay. Incidentally, both cables are classified as suitable for damp rooms and can therefore also be used in the bathroom without hesitation.

As already mentioned above, the NYM-J 3x1.5m² sheathed cable can generally be used for all light and socket circuits. However, if light and sockets are to run via one circuit, it is recommended to feed the respective room with a 3x2.5mm² cable. The 3x2.5mm² is also recommended for pure socket outlet circuits to avoid material stress due to heating of the cable. In principle, however, a 1.5mm² cable with 16A fuse protection should not be longer than 18m, taking into account the permissible voltage drop of 3%.

Except for pure lighting circuits, the NYM-J 3x2.5mm² sheathed cable shown on the left is therefore always preferable. The larger cross-section significantly reduces material wear, even with higher currents. Of course, you should proceed with caution here and always consider the intended use and the expected currents in the respective room. For example, if it is a supply line for a single balcony socket, a 3x1.5mm² NYM cable can also be used without hesitation.

What different light circuits and switches are there?

There are different lighting circuits, each of which requires specific wiring types and switch models. You therefore need to decide at the planning stage where you want to have lights and where you want to switch them on and off. For example, you usually switch the bathroom with a single light switch (switch-off), whereas you may need 2, 3 or even 4 switches for the hallway lighting (changeover or cross switching). Perhaps you are also planning two different lamps in your living room, which you would like to switch from one place, where a series connection is then required, for example (two separate switch-offs are also possible).

Off switch

The simplest variant is the so-called switch-off, where a lamp can usually only be operated with a single switch. Here, only phase L is required on the switch and “switched L” as the supply line to the lamp. A simple light switch (off switch) should be used for this circuit:

Changeover circuit

The changeover circuit usually consists of two switches at different locations, which are connected to each other using corresponding wires. The corresponding wires are two wires that connect the two changeover switches. Two changeover switches must be used for this circuit:

Cross circuit

The cross circuit consists of at least 3 switches and can be increased in any number. Here, too, the switches are connected to each other by means of corresponding ends, whereby the two outer switches are changeover switches and each switch in between is a cross switch. Two changeover switches and any number of cross switches can be used in this circuit:

Series circuit

The series circuit consists of a switch with two separate rocker switches, which can control two different lights in a room independently of each other. The switch is fed with phase L and two “switched L” as the supply line to the two lamps. A simple series switch must be used for this circuit:

Choosing the right junction boxes (distribution boxes)

There are now two options when selecting the required junction boxes, whereby one junction box should always be planned for each room. The respective room supply lines are laid in the junction boxes and then fed into the rooms from these. It does not matter whether you have planned a common supply line for light and sockets or two separate lines for light and sockets, as the junction boxes provide enough space for subsequent wiring.

Traditionally, junction boxes were used here, which were usually positioned directly above the light switches under the ceiling. This variant is still popular today, although I would not recommend it. From a technical point of view, there is actually nothing to be said against it, but these white covers don't necessarily look nice and you have to plan (at least) one additional junction box per room. Fortunately, we have already gone one step further and are trying to reduce the number of boxes required to a minimum.

For this reason, so-called flush-mounted combination boxes (flush-mounted device box with terminal compartment) were developed, which combine the classic flush-mounted device boxes and the junction box in one. We therefore save one box per room and can also dispense with the unsightly white cover under the ceiling, as everything disappears behind the light switch. This means that all the wiring in a room takes place behind the light switch and can be done without a ladder. In these combi boxes, there is a terminal compartment on the right and left, which offers plenty of space.

The entire distribution of a room then takes place in this one box, the supply line and all outlets (sockets, light outlet) are fed into this box and wired. The light switch is then inserted later and nothing more is visible. It is of course still possible to arrange several switches next to each other or on top of each other, as these boxes can be easily connected to each other and also to conventional flush-mounted boxes.

Connection of individual lines

To connect individual wires together, so-called cable clamps are required, which are also commonly known as Wago clamps. A single manufacturer has managed to position its product on the market and in the vernacular in a similar way to “Tempo” or “Zewa”.

Wago clamps are available in various sizes and shapes, differing mainly in the number of cores to be connected (2-5) and whether they have a lever or simple spring mechanism. For NYM cables, Wago clamps with or without a lever can be used, whereby those without a lever are always preferable as they are much more space-saving, which can be relevant in a small junction box. The wires are simply inserted into the Wago clamps and secured against slipping out. If you want to get a wire out again, simply turn the Wago clamps slightly while pulling. According to the VDE standard, Wago terminals should not be used in sub-distribution boards and should therefore only be used in junction boxes. If it is absolutely necessary to use Wago clamps in the sub-distribution board for certain reasons, these must always be secured with a top-hat rail holder and must not lie loose in the sub-distribution board.

The use of screw terminals (luster terminals) in junction boxes should be avoided as a matter of urgency. Even if this type of connection can still be found in many existing systems, it is no longer state of the art. Due to material movement caused by temperature differences, the screw terminals can become loose over time, which can lead to increased resistance, temperature and, in the worst case, sparkover and fire. This risk does not exist with Wago terminals, as a permanent connection is made by spring pressure, which can also withstand minor material movements.

This information is very important, as bolted connections are still used in sub-distribution boards in particular and should be retightened at regular intervals. However, the risk here can be considered very low, as we can assume that this is only carried out in a fraction of all systems operated in Germany and yet houses do not burn down every day. However, it should not be completely neglected, as I myself have experienced a fire caused by a loose terminal in a sub-distribution board, but in this case the terminal was not tightened correctly by the electrician during installation. I don't want to spread fear with this tip, but I do want to create an understanding of this risk. However, if you have the VDE check carried out on your electrical installation at regular intervals, you can reduce the risk to a minimum and will probably not experience such a case in your entire life.

What needs to be considered for special consumers?

What are special consumers?

In this case, special consumers include, for example, instantaneous water heaters, ovens and hobs, i.e. consumers that require special attention during planning, as they sometimes require different circuit breakers and supply cables. These are heat-generating loads, which always have a higher wattage and therefore sometimes require higher fuse protection and cable cross-sections.

What needs to be considered with instantaneous water heaters?

With instantaneous water heaters in particular, we are quickly talking about an output of up to 33 kW, which of course cannot be realized with a 16A LS and a 3x2.5mm² cable. With a 16A LS, for example, you can supply consumers up to a maximum of approx. 3.6 kW, which is calculated as follows:

Watt = Ampere x Volt (16 x 230 = 3,680 Watt) A circuit fused with 16A (1.5 mm² cable) should therefore not be permanently loaded with more than 3.5 kW, short-term peaks of up to 3.6 kW are perfectly OK.

Caution: Fatal errors often occur, especially with mini instantaneous water heaters with normal Schuko plugs. Some of these have 4.4 or 5.7 kW and must therefore not be connected to a normal household socket with a 1.5 mm² cable cross-section, despite the Schuko plug. Even if these appliances draw 20 or 24 amps of rated power, this does not necessarily mean that the 16 amp fuse will blow promptly. During this time, the cables can become dangerously hot, which can lead to a cable fire. It is essential to use a cable of at least 2.5mm² and an appropriate fuse.

The following table can be used as a good guideline, which specifies the cross-sections and fuses for certain instantaneous water heater outputs. From 6.5 kW, these must always be supplied with 400V, which also places additional requirements on the fuse protection and supply cable.

Source: Stiebel Eltron

For a 400V connection, all 3 phases (L1, L2, L3) must be used. In this case, 3-pole miniature circuit breakers with appropriate fuse protection should always be used. These have a decisive advantage over 3 individual circuit breakers, as all 3 phases are always disconnected in the event of a short circuit on a single phase. Even when working on the instantaneous water heater, it is therefore not possible for one phase to be inadvertently disconnected. These 3-pole circuit breakers are placed on the top hat rail of the sub-distribution board in the same way as single-row circuit breakers and fed through the miniature circuit breaker (RCD) via the phase rail.

What needs to be considered for kitchen consumers?

In the kitchen, there are usually the following appliances that require our special attention:

Stove (sometimes also separated into hob and oven)

Washing machine (can also be located in the bathroom or utility room)

Dishwasher

In the case of a stove or a variant with a hob and separate oven, the appliances should always be selected in advance, as these and the individual values are decisive for planning the cable cross-sections and fuse protection. In many cases, a single oven has less than 3.5 kW and is connected using a Schuko plug, so a simple socket can be provided for this variant, which is connected using a 1.5 mm² cable and has its own 16 A circuit breaker. Of course, even in this case it would not hurt to connect directly to a 2.5mm² cable, but this is not absolutely necessary.

A 5x2.5mm² NYM cable is provided for a combination appliance or a hob with the corresponding power, as you are always on the safe side with this. Depending on the respective appliance power, a fuse protection of 16A is usually sufficient. A 3-pole circuit breaker is also provided here. In many older installations, the variant with a 3x2.5mm² cable and a 1-pole 20A circuit breaker is often still found, which is also sufficient for many devices.

For the dishwasher and washing machine, we can keep it relatively simple and short. Both appliances should have their own supply line and socket at the future installation location. A 16A circuit breaker is provided for the fuse protection in each case. A 3x1.5mm² NYM cable is sufficient for the supply line.

Start the implementation!

Where do the cables have to be laid and are there minimum distances?

When laying live cables, it is imperative that uniform positions and minimum distances are observed, known as “installation zones” for short. Valid standards and regulations such as fire protection, safety regulations and accident prevention should also be observed. In principle, cables can be laid “surface-mounted” or “flush-mounted”, although nowadays only the “flush-mounted” variant is actually used in living rooms, or do you want to see your cables from the sofa all day long? ...probably not!

The applicable installation zones are shown in the illustrations below. Compliance ensures that the risk of cable damage is avoided as far as possible in the future. Especially when hanging pictures or shelves, damaged cables occur time and again, which could actually be avoided if the installation zones were observed. It should also be noted that we have slightly different installation zones in the kitchen area, which you can also see in the illustrations. If you keep a distance of 15 cm on both sides of the installation zones in future, you will probably never find yourself in the unfortunate situation of accidentally hitting a pipe with your nails and screws.

How do you make the cable slots?

You urgently need a slot cutter to make the cable slots. If you try to make the slots using only a hammer and chisel, you will only make more work for yourself when closing the slots later. The money for a slot cutter is therefore a good investment, and these days they don't have to be that expensive. There are many offers on Amazon for devices that are perfectly adequate for private use, but professionals should of course opt for a higher-priced branded product for regular use. However, I can recommend the following product to you without hesitation, as I have already carried out a complete home renovation with this slot cutter myself.

Milling slots in masonry and concrete is a common method of laying cables and pipes safely and invisibly. With this technique, it is important to choose the right procedures to ensure both structure and safety. To this end, it is essential to observe the applicable regulations and standards, such as DIN 18332 for walls and DIN 18350 for concrete. Among other things, these standards specify how deep and wide the slots may be so as not to jeopardize the stability of the wall. It is also advisable to carry out precise planning before milling in order to avoid damaging existing cables or pipes. Wearing suitable protective equipment, such as safety goggles and hearing protection, is also essential to avoid injury. With the right preparation and adherence to regulations, slit milling can be carried out efficiently and safely.

Slotting in brickwork

The DIN EN 1996-1-1 standard (brick walls) only describes the production of slots in load-bearing masonry walls. This regulation does not apply to non-load-bearing walls, as the load-bearing capacity of the building is not affected. Creating horizontal slots in brickwork requires special attention, as the cross-section of the bricks is reduced over the entire length of the slot. For this reason, horizontal slots are generally not allowed to be as deep as vertical slots and are only permitted in thicker walls. Slots with a maximum length of 1.25 m are only permitted from a wall thickness of 15 cm, while a wall thickness of at least 17 cm is required for recesses without a length restriction.

The positioning of horizontal slots is also more restricted than vertical slots. They may only be located within 40 cm above or below the bare ceiling and are only permitted on one side of the wall. However, there are exceptions: With a maximum depth of 10 mm and a wall thickness of at least 24 cm, opposite slots are also permitted. In many cases, such as for installations in kitchens or offices, horizontal slots in the middle of the wall are necessary. However, these should be avoided wherever possible and kept as short as possible, as the risk of failure (e.g. buckling) is highest in the middle of non-load-bearing walls. It is also important that horizontal slots with a limited length maintain a distance of 49 cm from openings and recesses and twice their own length from other horizontal slots.

Vertical slots generally pose fewer problems than horizontal slots. From a wall thickness of 12 cm, such slots may also be inserted subsequently. The distance to openings and other recesses should be at least 11.5 cm. Slots that are created in brickwork connections are not an issue here, as these are usually already taken into account in the planning phase and are of no significance for the extension of the electrical installation. Several adjacent vertical slots must be at least one width apart and the width of both the individual and the total slot per 2 meters must not be exceeded.

Important: For wall thicknesses over 24 cm, vertical slots can be made up to a height of 1 m above the floor with a maximum depth of 8 cm and a width of up to 12 cm.

Slotting in concrete

With concrete walls, on the other hand, it is much more difficult to create slots, as even a few small slots can have a significant impact on the stability of the building, which would then require a great deal of renovation work. For the reasons mentioned above, I therefore do not recommend slots in concrete walls and recommend consulting a structural engineer if in doubt. In principle, however, the plaster thickness can certainly be checked, as most concrete walls and ceilings in living spaces have a sufficiently thick layer of plaster. If this is the case, the slits can of course be made in the plaster without any problems and without slitting the concrete itself.

Drill device boxes

How are the cables attached?

It is important that the installed cables sit firmly in the slots and do not protrude beyond the edge of the slot, otherwise it will not be possible to plaster cleanly. There are various methods to hold the pipes firmly in position so that nothing stands in the way of subsequent plastering.

My favorite variants here are wall groove clips and dowel clips, as you are equipped for a wide range of application situations and can guarantee a secure hold for the cables.

You can get wall groove clips from various manufacturers and in different sizes, so you can easily choose the right variant for every application yourself. I personally like to use Fischer products, but clips from other manufacturers also work very well, just try them out or simply click on the image to go directly to the product.

Dowel clips work very well when used in concrete walls. As cables are often laid in concrete walls only in partially “porous” plaster, the wall groove clips often do not hold. For this application, you've come to the right place with the wall plug clips, as they are hammered into a previously drilled hole and reliably hold your cables in the desired position. However, it is also recommended that you place plaster stamps at certain intervals. A plaster stamp is nothing more than a small amount of mixed plaster that you press into the cable slot for additional stabilization. This provides additional stability and holds the cables securely in the designated cable slots.

Prepare cables for later connection

As long as we are still busy laying the cables, we don't necessarily need to strip them yet, although of course there is no reason not to and you can therefore decide for yourself. I will of course discuss stripping later, but at this stage I would only insert the cables into the boxes and not work on them any further.

The cables are now pulled into the sockets and the sub-distribution board, whereby you should never cut the cable ends too short, as this could put you in an annoying situation, true to the motto:

“What's off is off”

Even if the saying is a little reminiscent of a failed visit to the hairdresser, it is essential for completing your electrical installation without any obstacles. As a guideline, you can take twice the diameter of the box opening for boxes and the length of 1x longest side + 2x short side of the sub-distribution board. It is very likely that you will cut off a lot of cable during the final connection, but it is still important to be prepared for any type of final cable laying and not have to rely on the available cable length when laying the cables. The cables are usually fed into the sub-distribution board from above, but this is for a practical rather than a regulated reason - the cables usually just come from above.

Good preparation also includes labeling the cables during installation. As you will have noticed, the cables are all the same soft gray, which is why they are unfortunately indistinguishable from one another once they have been laid. In order to save you the agony of having to determine the diameter later, you should label the cables accordingly, which you can either do with a strip of adhesive tape or directly on the gray sheath, which I would definitely recommend. Adhesive tape can sometimes tear off, which is why the variant with a waterproof felt-tip pen directly on the cable is probably recommended and common.

How are the pipes and boxes plastered/filled?

Puhh...if you've reached this step, then you've really achieved something and can give yourself a pat on the back. Once all the cables and sockets have been laid, you can finally plaster them or the cable slots. As this article is about an electrical installation, I don't want to go into detail about how to mix the filler and use a trowel, and I assume that anyone should be able to do this without instructions...., especially if they have previously attempted an electrical installation. However, I would still like to give you a few small tips on this work step.

It is advisable to close the boxes with plaster lids, as this keeps the cables free of plaster/filler and also prevents the entire box from being filled with it. The plaster lids are extremely inexpensive and can be purchased online or at any DIY store. The lids close the tins completely and are easy to find even after plastering thanks to their red flags. As the flags are very thin and flexible, they do not interfere in any way and do not get in the way when smoothing with a trowel. After the drying phase, the thin layer of filler can simply be broken off by pressing lightly on the tin and the lids removed.

To close the slits and work on the tins cleanly, I would recommend simple Knauf Rotband surface filler. Rotband is amazingly inexpensive and can be easily applied by anyone. For the finish, I always like to use ready-to-use Knauf Fill&Finish Feinspachtel from the bucket, as it has a perfect mixing ratio, doesn't clump and is very easy to sand. And I can promise you one thing, once you've used Knauf Fill&Finish, you'll never mix your own fine filler again, because the stuff is just awesome!

Final assembly, but how?

The final installation is probably the best part of a new electrical installation! The work is clean, dust-free and simply fun, plus you get a little closer to completion with every additional socket or light switch, which is simply a great feeling.

For the final assembly, we now start by stripping all cable ends, i.e. removing the gray sheath and exposing the inner cores. It is extremely important that neither the copper wires nor their insulation are damaged during this step, so handle the cable ends with extreme care! During my training, I learned how to strip the cable with a simple knife, but there are much better special tools that allow you to cut and remove the gray protective sheath quickly and cleanly. It is important to know that you only have to cut the outer layer of the sheath and that it can then be broken cleanly and easily.

To do this, you use the so-called stripping tool, which is of course available from countless manufacturers and in a wide variety of shapes. From experience, however, I would recommend two designs or models. With these two stripping tools, stripping will be very easy and your wires will remain 100% undamaged. Due to the small and round design, you can get deep into the cans and remove the sheath very easily. To do this, the stripper is pushed over the cable, pressed together and rotated 360°. You can then bend the cable slightly, break the sheath and then simply pull it off. We now do this with all existing cable ends in the sockets, light switches and the sub-distribution board.

A little tip: For the sub-distribution board, you should first push a small piece of sheathing back over the wires of the individual cables. Simply use the piece that you previously labeled and have now cut into a small 2-3 cm piece. This will keep the cables labeled until you start wiring the sub-distribution board.

Installing sockets

As the sockets are probably the easiest to install, it is best to start with these. Manufacturers of higher-quality products actually only use spring terminals, which always ensure sufficient pressure on the wires to keep resistance as low as possible. Spring terminals also make installation much easier, as the stripped wires are simply pushed in and then secured against being pulled out. For stripping, it is best to use a wire stripper, although the stripping tool theoretically also has an integrated stripping option. I deliberately don't want to give you a stripping length, as this can actually vary slightly from manufacturer to manufacturer and should always be implemented according to the manufacturer's instructions. However, as manufacturers often think ahead, it is now common for every manufacturer to print the stripping length on the back of their sockets and light switches. So simply look at the sockets you have chosen and remove the insulation to the specified length, which should probably be between 10-13 mm. As you can see in the picture, the PE (green-yellow) or protective earth conductor is connected to the middle terminal. The phase L (brown) and the neutral conductor N (blue) go into the terminals on the left and right, whereby it theoretically does not matter which goes to the right and which to the left. Due to the alternating current, the plugs have reverse polarity protection, which is why the polarity does not matter during installation. The live phase L is usually on the left-hand side, but you should at least make sure that it is on the same side in all sockets, even if it is the right-hand side.

If it is a double, triple or even quadruple socket outlet, this is of course no problem at all. The supply cable goes into one of the two outer sockets and is connected to the first socket here. From the first socket outlet, a short end of the cable then goes into the adjacent socket outlet and connects this one too (and so on). As the sockets for L, N and PE each have two connections, these can be bridged as often as required. Due to the connection channels of the flush-mounted boxes, the bridges (connecting cable) can simply be pulled from box to box.

Installing the light switch

Installing the light switches is a little more challenging than installing a simple socket. Fortunately, you already have some practice with the socket installation and should now be able to master the light switches without any problems! As we have different light switches, you should definitely refer to the section “What different light circuits and switches are there?”, in which I have already explained the different light circuits and you can also find the corresponding wiring diagrams/connection diagrams.

Light switches also usually have spring terminals and no screws, so installation is just as easy as with sockets. However, it is important to pay attention to the type of circuit, as a different light switch model must be used for each light circuit. Each of the different light switches is of course also connected slightly differently, but each manufacturer prints the connection diagram on the back of the respective light switch, which is why installation can be carried out without any problems. As with the sockets, the correct stripping length must also be observed for the light switches, which can also be found on the back or side of the light switch.

Install instantaneous water heater

As already explained in the planning section, instantaneous water heaters are intended for connection to the three-phase mains (L1, L2, L3) due to their high power consumption and therefore also have their own connection cable and 3-phase circuit breaker. Under-dimensioned cables in combination with over-dimensioned circuit breakers therefore represent a clear fire hazard. From a connected load of 12 kW, a permit must be obtained from the respective energy supply company before commissioning an electric instantaneous water heater, but this size is not usually necessary in normal households. Instantaneous water heaters are three-phase consumers with a symmetrical load, which means that a connection to the neutral conductor is not usually required. The connection is only made with L1, L2, L3 and PE. Instantaneous water heaters are usually supplied with a mounting plate, which is first attached to the wall and the instantaneous water heater is then connected to the mounting plate using the nut (figure numbering: 2). For electric water heating with instantaneous water heaters for bathing or showering, DIN 18015-1 in 5.2.5 “Residential installations” requires a three-phase cable with a permissible current carrying capacity of at least 35 A.

Installing the stove

To connect the stove or oven, an appliance box is normally provided directly behind the planned installation location of the oven, which is then fitted with a surface-mounted stove connection box. These stove junction boxes are often still sold with screw connections, although I would also recommend using a box with spring terminals (Schneider stove junction box). In addition to the junction box, you also need a so-called stove connection cable, which can usually be bought ready-made and in the correct dimensions.

There are usually a total of six connection terminals on the back of the stove (3 terminals for the phases, 2 terminals for the neutral conductor and 1 terminal for the protective conductor). To begin with, the connection cable is now connected to the stove. To do this, connect the cable to the respective terminal, which is marked accordingly on the oven and connected according to the color scheme. The screw terminals should be tightened very firmly, as this is the only way to ensure a perfect and secure connection and avoid the risk of fire. If the stove is to be operated with a voltage of 230 volts (3-wire L, N, PE), so-called bridges are required. In order to assign a jumper to the correct contacts of the stove, it is essential to use the wiring diagram of the respective model, as there may be deviations depending on the manufacturer. However, most manufacturers usually print their wiring diagram on the back of the stove or the cable cover plate, which is why the paper installation instructions are only rarely required. In most cases, the jumpers are also located behind the connection block and are therefore very difficult to lose.

Once all the cables have been connected to the back of the appliance, the wires can now be connected to the oven connection box. Ideally, the connection cable should not be shortened, as it should be long enough to allow the oven to be easily pulled out of the cabinet when connected. The PE protective conductor can now be connected to the junction box, whereby this must always be longer than all other wires in accordance with the standard, as it remains connected to the box the longest when the cable is pulled out. However, many manufacturers now also ensure this by arranging the PE terminal so that it is slightly offset, thus ensuring that the PE wire is the last to be pulled out. The next step is to connect the neutral conductor and phases L1-L3. Finally, the connection cable must be secured with the cable holder to protect the connections against tension.

Equip and connect the sub-distribution board

Although there are a few things to consider when connecting the sub-distribution board and it may seem daunting at first, the sub-distribution board is actually the most beautiful part of the entire electrical installation. This is where you can fully express yourself artistically and be proud of a flawless distribution board with perfectly bent wires at the end. This example shows a 4-row sub-distribution board with two rows of residual current circuit breakers and miniature circuit breakers. It also has a connection block and surge protection, i.e. a typical residential distribution board. I would also like to point out in advance that with most makes of RCDs and miniature circuit breakers, it does not matter whether they are fed from above or below. Typically, however, the RCDs are fed in from above and the MCBs from below using a phase busbar.

First, the supply line is connected to the connection block, whereby this can either come from above or below, which always depends on the respective installation situation. The RCDs with N + L1, L2, L3 and the PE rail (earthing) are then fed in from the connection block. The individual wires of the supply cable should be stripped in such a way that the bare wire reaches under the second screw and yet no bare copper is visible from the outside. This procedure is important because the necessary protection against accidental contact must always be maintained within the sub-distribution board and bare cables in the contact area must always be avoided.

The N-rails (neutral conductors) are then fed in from the two RCDs, whereby it is important to note that there must be a separate N-rail for each RCD and that these must not be connected to each other, as otherwise the function of the RCD would no longer be guaranteed (shown in the picture). Unless a pre-equipped sub-distribution board is used, the internal connections are always made with flexible 10mm² cores in the correct color. Please note that flexible cables may only be inserted into the screw connections with wire end ferrules; installation without wire end ferrules must be avoided at all costs!

The cables of our individual circuits can now be connected. To do this, the live wires L1-L3 on the right-hand side of the housing are pulled to the desired top-hat rail and routed in the direction of the circuit breakers with a clean 90° bend. At the height of the required circuit breaker, the wires are then inserted into the screw terminals using further clean bends and tightened. If it is a three-phase connection (e.g. instantaneous water heater), this is supplied via a 3-phase circuit breaker, to which L1 (brown), L2 (black) and L3 (gray) are now connected (shown in the picture). The PE protective conductors can now also be connected, whereby there is only a single PE busbar here and there is no separation between RCD 1 and RCD 2 (all protective conductors on the same busbar). The conductors can be laid neatly up to the desired terminal and then shortened to the required length; there is no need to lay unnecessary bends or plan a safety length. Now it is the turn of the neutral conductor N, which must be laid on the corresponding N-rail of the incoming RCD. If the wrong N busbar is used, the RCD will malfunction, which can be life-threatening in the event of contact current. Otherwise, the respective wire is also laid neatly to the terminal and shortened to the minimum length.

As soon as all cables are connected, each screw connection should be retightened and checked for correct hold.

Conclusion

Why is it worth planning and installing an electrical installation yourself? In conclusion, it is definitely worth planning and implementing an electrical installation for your house or apartment yourself. Not only can you save money, but you can also incorporate your individual needs and wishes into the planning. However, it is important to observe the basics of electrical engineering and take all the necessary safety measures. But if you take your time and proceed carefully, you will be rewarded with a successful DIY electrical installation. With the right tools and materials and the knowledge of how to wire safely and install switches and sockets, nothing will stand in your way. Even setting up a power grid is no longer a challenge for you. But remember, the costs can vary greatly depending on the size of the project and the materials used. Overall, a DIY electrical installation offers many advantages such as flexibility, individuality and cost savings. So treat yourself to this DIY fun and plan and install your electrical installation yourself! However, please bear in mind that the expertise, consultation and supervision of a specialist company (master company) is essential. Only by calling in a specialist company can you comply with all laws/regulations and avoid danger to life, limb and property.

Summary of material and tools:

Tools: Voltage tester, needle-nose pliers, telephone pliers, side cutters, electrician's screwdriver, electrician's set, slot cutter, cable stripper, wire stripper, crimping pliers, drill, plaster cup, putty set

Material: Sub-distribution board, overvoltage protection device, terminal blocks, NYM-J sheathed cable 3x1.5mm², NYM-J sheathed cable 3x2.5mm², NYM-J sheathed cable 5x1.5mm², NYM-J sheathed cable 5x2.5mm², flush-mounted appliance box, flush-mounted appliance box with terminal compartment, plaster cover, Wago clamps, 3-pole circuit breaker, wire end ferrules, wall groove clips, dowel clips, nail clips, cable ties, electrician's plaster, Rotband adhesive plaster, Rotband surface filler, Knauf Fill&Finish, sockets, light switches, instantaneous heaters

Comments